high quality open impeller slurry pump manufacturers

Latest articles

target=_blank>Slurry Pump

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreSlurry Pump

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreIn AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreThe concentration of solids in the slurry - measured as a percentage of the total volume.

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreHow does a dredge pump work?

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreTo find out more about Aier slurry Pumps, please >contact us.

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreMud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreSump drainage or washdown

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

high quality open impeller slurry pump manufacturers...

high quality open impeller slurry pump manufacturers 【high quality open impeller slurry pump manufacturers】

Read More

Popular articles

- Selecting And Operating A Slurry Pump

- The first major requirement for >slurry pumps is to provide adequate service life. The erosive and corrosive effects of slurries, such as the impact of high velocity flow of liquid/solid mixtures, can be really challenging. In many applications, some of the solids in the mixture are larger than the particles normally specified; therefore, the pump should be able to pass through them without causing any damage or operational problems.

- Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

- Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

- Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

- Firstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

Latest articles

-

To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

-

High head (i.e. the height to which the pump can move the liquid)

-

Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

-

All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

-

Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

-

As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

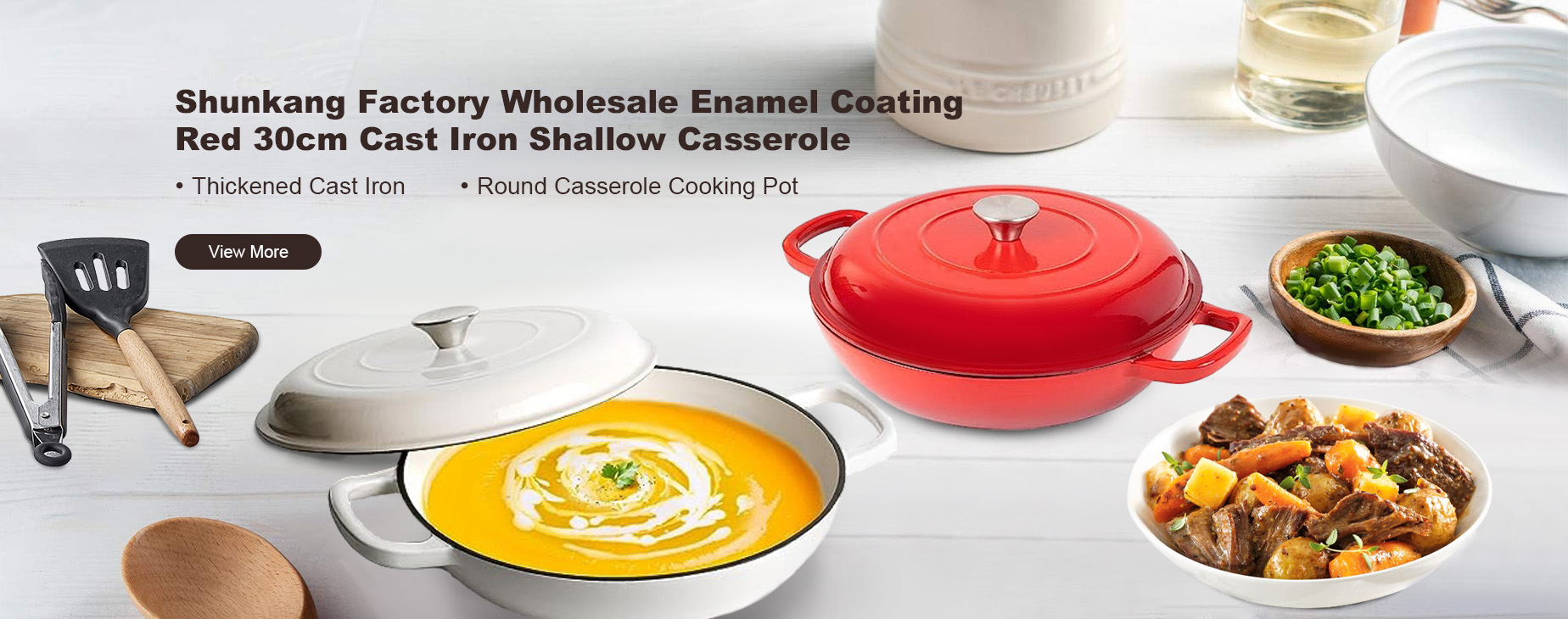

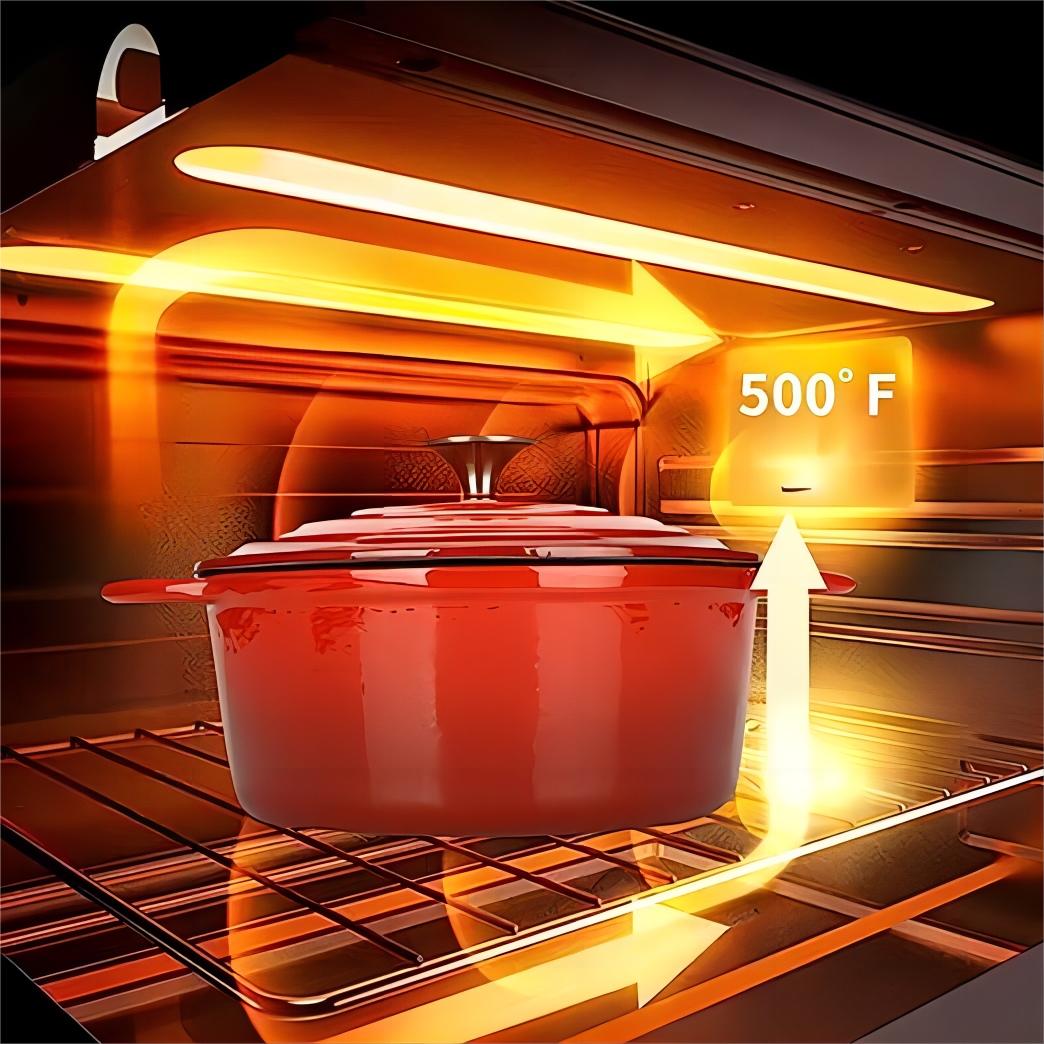

Round Cast Iron Griddle Pan, on the other hand, are great for cooking single items like steaks, burgers, or vegetables. The round cast iron griddle pan's compact size makes it easy to handle and store, and its round shape makes it easy to flip food. The round cast iron griddle pan's raised edge is also ideal for cooking dishes with sauces or gravies, preventing spills or drips.

Its vibrant colors, ranging from classic white to bold shades of blue, red, or green, add a pop of visual delight to any kitchen decor Its vibrant colors, ranging from classic white to bold shades of blue, red, or green, add a pop of visual delight to any kitchen decor

Its vibrant colors, ranging from classic white to bold shades of blue, red, or green, add a pop of visual delight to any kitchen decor Its vibrant colors, ranging from classic white to bold shades of blue, red, or green, add a pop of visual delight to any kitchen decor small enamel pot with lid. Its retro aesthetic, reminiscent of bygone eras, adds a nostalgic touch to modern culinary practices. Whether used as a serving dish or displayed on open shelving, it becomes a decorative element that tells a story of culinary traditions.

small enamel pot with lid. Its retro aesthetic, reminiscent of bygone eras, adds a nostalgic touch to modern culinary practices. Whether used as a serving dish or displayed on open shelving, it becomes a decorative element that tells a story of culinary traditions.